Get an Extra 30% off Clearance Items With Code SAVE30 (click here)

PC Water Cooling Components - Compression Fittings

Welcome back to the Component Series. We hope to help builders both new and old to understand their options when it comes to the components in their custom water loops. We’re starting a massive chapter in the Components series today: Fittings. Since that category is way too big to fit into a single post, we’ve broken it down by fitting type. Today’s entry is on compression fittings.

A collection of compression fittings for both rigid and flexible tubing.

Where’s the compression in a compression fitting?

All compression fittings are made of at least three parts: an o-ring on the threads (common to all water-cooling fittings), the body of the fitting that screws into a port on whatever component it’s serving, and a collar that screws down onto the body.

Compression refers to the pressure that’s put on the tubing when the locking collar is tightened down. While compression fittings for flexible tubing and rigid tubing are different, they work on the same principal of compression forming a seal against the tube.

There are two types of compression fittings, each made for the two types of tubing we use in our water cooling work: flexible tubing compression fittings and rigid tubing compression fittings. Let’s look at each in turn.

Flexible Tube Compression Fittings

In PC water cooling, flexible tube fittings really only come in 2 forms: barb fittings and compression fittings. The difference between the two is the locking collar.

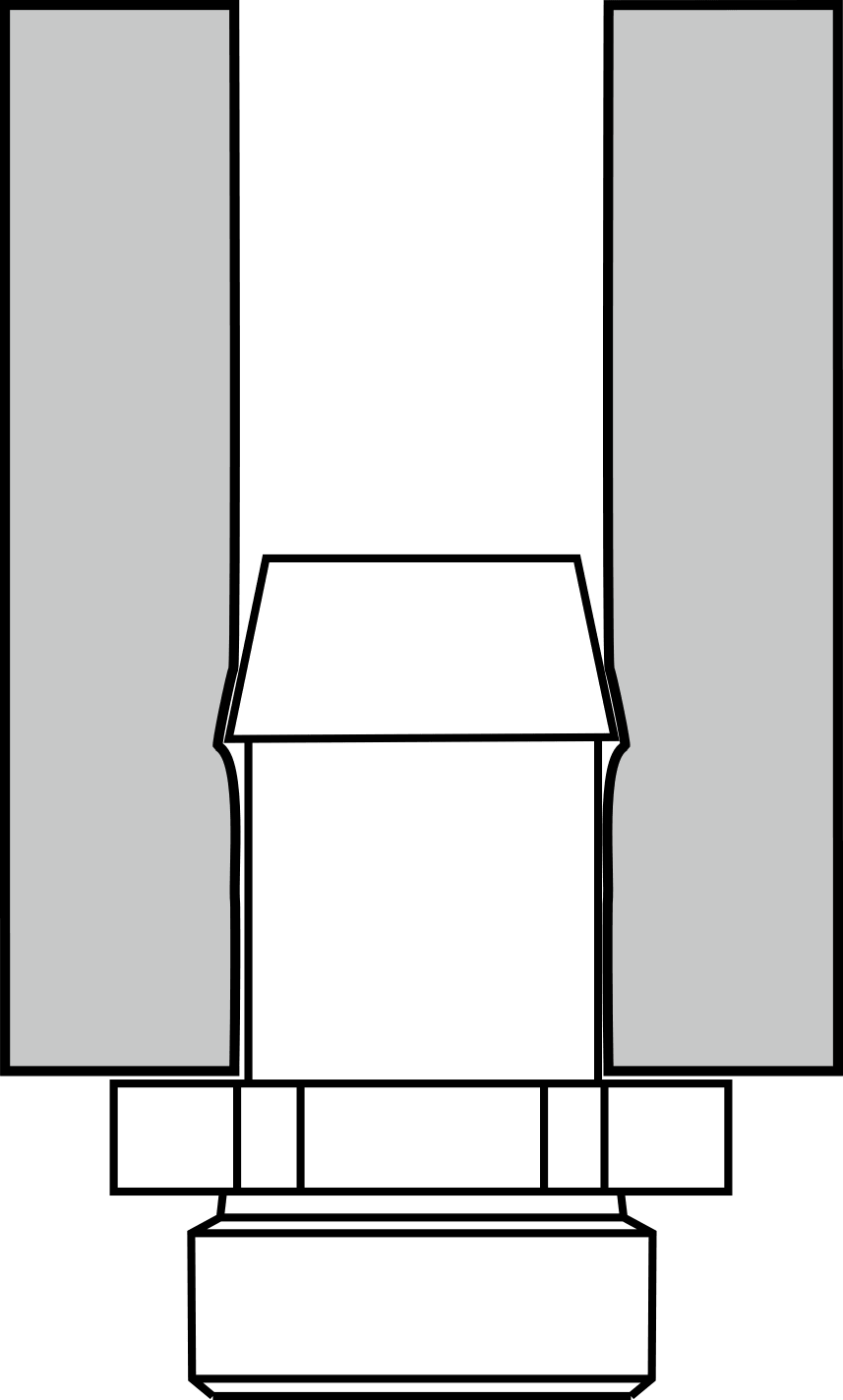

Take a look at a standard barb fitting and how it fits into the tube:

How standard barb fittings fit inside flexible tubing.

Barb fittings are typically installed with clamps around the tubing to prevent it from coming off or leaking. The seal is made by compressing the tube against the outside surface of the barb. While clamps are a simple and effective method, they can be finicky and not all clamps are created equal.

Flexible-tube compression fittings are just better-designed barb fittings.

Looking at these images it’s clear that flexible tube compression fittings are nothing more than barb fittings with a threaded upper collar added. The locking collar on a flexible-tube compression fitting screws down onto the barb portion, and the sides and the upper edge of the ring compress the tube onto the barb portion, holding it in place more effectively than a clamp.

How flexible tubing compression fittings seal with their locking collar.

The diagram and cross section above show clearly how flexible-tube compression fittings work. The locking collar is almost snug against the outside of the tubing. Notice how much narrower the space between the barb portion of the body and the top of the locking collar. This is where the compression happens.

Because the fitting is designed to function with both the inside of the tube and the outside, the dimensions of both have to match the fitting. Flexible tubing is typically described with two numbers: inside diameter followed by outside diameter. If your tubing is 12mm/16mm for example, you’ll have to get fittings that are also 12mm/16mm. Otherwise the tubing will either not fit at all or not seal properly and potentially leak.

Flexible tube compression fittings have long been the standard for builds using flexible tubing. Their simple design and effective function make them an obvious choice.

Flexible tube compression fittings in a custom water-cooled PC. Image credit: Million-Dollar-PC.com

Rigid Tube Compression Fitttings

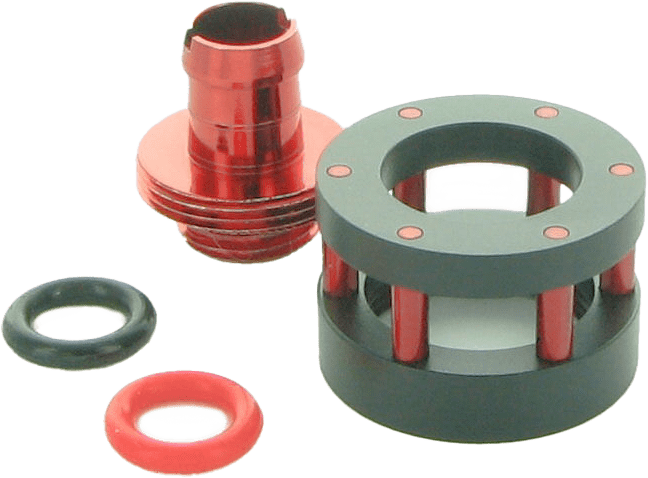

Like flexible tube compression fittings, rigid compression fittings seal by compression as the locking collar is tightened down. Unlike those fittings though, nothing actually goes inside the tube. There’s no barb portion like there is with flexible tube fittings. Since rigid tubing is, well… rigid, an internal fitting isn’t required.

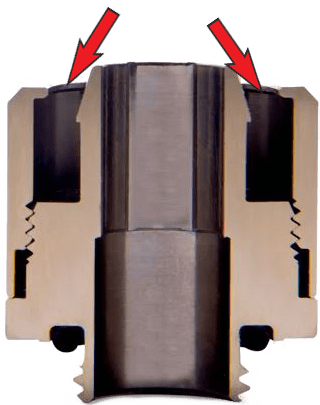

Rigid tube compression fittings work on the outside only.

Instead, rigid-tube compression fittings use o-rings to seal. There are always at least one o-ring inside the fitting that the tubing slides into, and another loose o-ring that slides onto the tubing after the locking collar. That last o-ring is what is compressed by the tightening of the locking collar and what makes compression fittings different from push-in rigid tube fittings.

The steps of installing a rigid compression fitting on your tube.

There is an exception to the rule: LED fittings. Unique among rigid tube compression fittings, fittings with built-in LED lighting have to utilize the same structure as flexible-tube compression fittings.

The surface of the body of the fitting where the outer o-ring would normally seal is taken up by an LED circuit, so instead they have an insert built into the body with internal o-rings.

Since these are inside the tubing, these are not truly compression fittings at all, but they are categorized that way because of their similarity in construction.

LED rigid compression fittings aren’t actually compression fittings at all.

If you plan to work with rigid tubing, rigid compression fittings are your only option. Thankfully they comes in a huge range of sizes, colors, angles and surface finishes to compliment your custom PC perfectly.

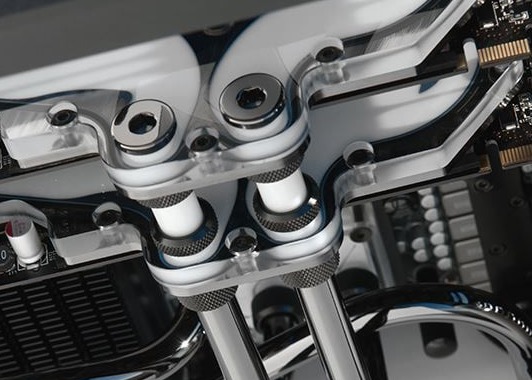

Perfectly-matched rigid compression fittings in a custom PC. Image credit: Million-Dollar-PC.com

Angled and Rotary Compression Fittings

Compressions fittings are available in four different angles as well as straight.

Compression fittings for both flexible and rigid tubing are also available with an angle built in. These are handy when you come have a complicated or tight-quarters situation with your tubing. You can get these in four degrees of angle: 30, 45, 60 and 90 degrees.

These angled compression fittings have an added benefit: the angled portion that the tubing goes into actually rotates 360 degrees around the threaded part. These fittings can be fully installed in a threaded port and still rotated in a complete circle. In fact, some compression fittings have more than one axis of rotation, allowing even more flexibility in your tubing run.

Multi-rotary compression fittings allow for wide adjustment in position and shape.

Tools

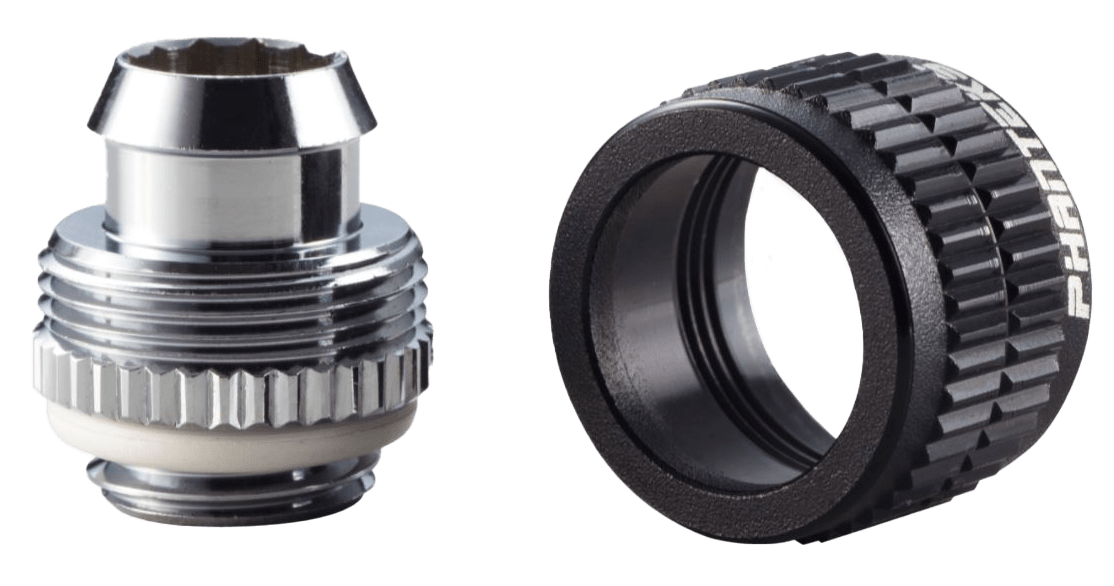

While not true of every compression fitting on the market, many of both types will come with some sort of design feature to allow tools of some kind to be used in their installation and removal.

Some are made with a shape formed into the inside diameter of the fitting to match a specific size of tool such as an allen wrench. Others will have a slot at the top of the barb portion to allow the use of a screwdriver or coin in turning them. Some offer a proprietary tool made specifically for that particular type of fitting.

Different tools can be used to install or remove different types of compression fittings.

You should always be careful when tightening fittings, but especially when tools are being used. Overtightening can lead to leaks or worse. This is especially true when working with acrylic. Acrylic is a strong material but it’s also brittle and far softer than the metal used to make fittings. Overtightening a fitting into a female port cut into acrylic can cause cracking from the pressure. Even if the material doesn’t crack immediately, the stress from overtightening can cause the cracks to happen later with changes in temperature.

An acrylic water block cracked from overtightening a rigid compression fitting.

Your choice of fitting is as important as any other choice in the component list of your custom water cooling system. Understanding your options is critical in making any decision. We hope we’ve helped to explain the nature and inner workings of standard compression fittings. Stay tuned to our Component Series as we sort through the wide range of fittings available to you today.